Centerlining in Manufacturing: Building Consistency for Better Performance

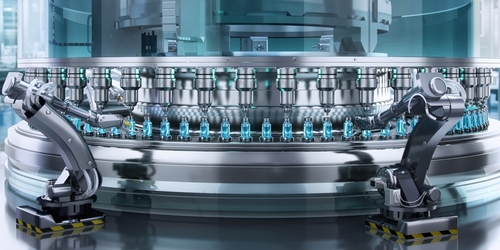

In today’s manufacturing environment, consistency isn’t optional; it’s the backbone of efficiency. A conveyor speed that’s slightly off or a sensor that drifts out of position may not sound like a big deal, but those small variations add up. They create jams, cause downtime, and disrupt product quality. Centerlining provides a way to prevent those issues before they start by locking in the ideal setup for equipment and keeping it there.

What is Centerlining?

Centerlining is the process of documenting the optimal settings for equipment — things like rail positions, belt speeds, sealing pressure, or sensor alignment, and making sure those settings are applied across every shift. Once these “centerlines” are identified, operators have a reliable playbook to follow, reducing reliance on memory or individual preference.

The method also ties directly into Lean Six Sigma. Within the DMAIC framework, centerlining plays a critical role in the Control phase, helping teams sustain improvements over the long term rather than sliding back into old habits.

Why It Matters

When centerlining is in place, the benefits extend across the operation:

- Fewer interruptions. Processes run smoothly without constant troubleshooting.

- More consistent quality. Products meet specifications across shifts and lots.

- Improved efficiency. Changeovers and training take less time because standards are clear.

These gains don’t just solve short-term issues; they build the kind of stability that allows teams to focus on higher-value improvement efforts.

Learn more about our manufacturing process improvement services.

A Practical Example

On a high-speed packaging line, inconsistent carton closure created recurring jams and stoppages. At first, it looked like a simple problem, but deeper review showed multiple variables at play: belt speed, flap tucker timing, air pressure, and sensor alignment.

By applying centerlining, the team identified the optimal ranges for those critical parameters, documented them, and marked them on the machines. Once standardized, the process stabilized. Jams were reduced, downtime dropped, and the line no longer required an operator to manually intervene.

Why Now

Margins for error in manufacturing are shrinking. Customers expect flawless quality, regulators demand compliance, and staffing models are leaner than ever. Many of the problems that slow down production don’t come from catastrophic breakdowns; they come from small variations that accumulate shift after shift.

Centerlining directly addresses this challenge. It provides a structured way to capture what works best and ensures it’s consistently applied. Unlike a major capital project, it’s a low-cost, high-impact improvement that helps teams get more out of the resources and equipment they already have.

Final Thoughts

Centerlining may not be flashy, but it delivers lasting impact. By standardizing process settings and eliminating variation, manufacturers can reduce downtime, improve quality, and create more predictable operations.

For organizations aiming to boost efficiency without heavy investment, centerlining offers a practical path toward operational excellence. Explore how our operational excellence consulting can help implement strategies like centerlining for long-term results.

Let cGMP Consulting help you streamline compliance, increase efficiency, and drive operational success. Contact us today to learn how our Operations Support Services can help you drive your initiatives forward.